Automatic bag forming filling sealing and top labeling machine

Introduction :

This machine are special design for packing granule product into square bottom bag .It is widely use for packing wheat rice bean grain and similar product .This machine unit are including ZLB500 Volumetric cup dosing system ,one set ZL520 vertical bag forming filling machine .one set ZLYB1000 linear bag forming sealing and labeling machine and one set output conveyor .It can make the nice bag with square bottom and fold the bag mouth and labeling .So the finished bag have a nice shape ,pretty outlook .

Work progress:

1,Automatic weighing and discharge the material

2,Automatic making the bag and filling the material

3,Automatic discharge the bag on the reforming mould

4,Bag mouth forming and clamping

5,Bag mouth trimming

6,First bag mouth folding

7,Heating press and reforming

8,Labeling sticking and pressing

9, output the bag

Details information of the machine

1,ZLB500 Volumetric cup dosing system with cover

The whole machine made by SUS304.Adopt China famous brand motor .Volume can be adjust from 75%-100% .Including the vibrate feeding device which special design for wet salt and mixed device.

Технически параметри:

Speed: 40-60time/min

Power :220V 50HZ 0.75KW

2,ZL520 Vertical bag forming filling sealing packaging machine

The unit of machine is especially developed for small bag packaging ,This machine can independently complete the bag making, filling (air filling or exhausting as option), sealing (hole punching as option ) code printing, and bag counting etc. adopt film automatic correction device .The machine frame and material contact part made by SUS304 .PLC and touch screen adopt by Siemens brand .Adopt Panasonic servo motor for horizontal sealing which is fast and stable .And Pneumatic parts adopt Air Tac brand .Main Electrical components adopt Omron and Schneider brand Which is easy to operation

Technical Parameters

Weighing Range: 500-1000gram

Packaging Speed:15-20 bags/min for 1kg 18-23bags/min for 500gram

Bag size: (80-340)*(60-250)mm(L*W)

Compressed air requirement: 0.6Mpa 0.65m³/min

Reel outer diameter: 400mm

Core inner diameter: 75mm

Machine weight: 800kg

Power source: 3kW 380V±10% 50Hz

Main Features and Characteristics:

A wide range of pouches: Pillow and Gusset pouches(option).

High speed: More than10-25 bags/min

Easy to operate: PLC controller and color touch-screen, fault indication on the touch screen.

Лесно се регулира: само около 10 минути за смяна на различни торбички.

Честотен контрол: скоростта може да се регулира чрез преобразуване на честотата в диапазона.

High Automation:unmanned in weighing and packing process,machine alarm automatically when failure.

Safety and Hygiene:No film, machine will alarm.

Алармата на машината се спира и спира при недостатъчно въздушно налягане.

Предпазните защити с аварийни превключватели, алармата на машината и спирането при отваряне на предпазните устройства.

Hygienic construction, the product contact parts are adopted sus304 stainless steel

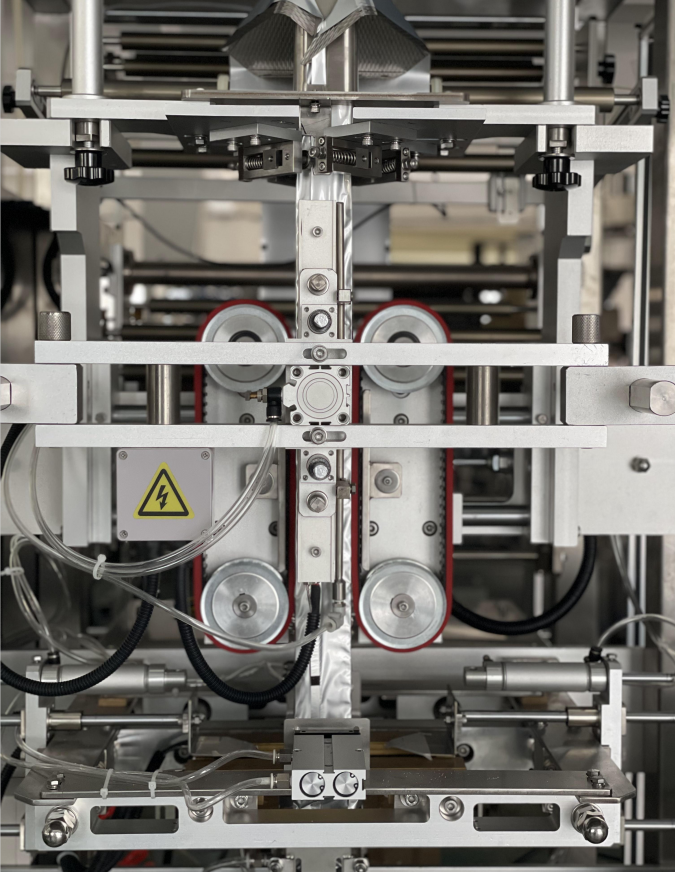

3,ZLYB1000 linear model bag forming sealing and labeling machine

This machine is special design for make the gusset bag with top labeling .After the full bag with product drop on this machine .This machine will carry the bag ,go through one time bag mouth folding and then stick the label.The machine frame made by SUS304 .PLC and touch screen adopt by Siemens brand .And Pneumatic parts adopt SMC brand .Main Electrical components adopt Omron and Schneider brand.This machine is working with automatic packaging machine to reach the finished bag top labeling .This machine can automatic reach the function of the label separated ,Label sending .Label detector and label pressing .

Technical Parameters

Speed : Max 18-25time/min

Accuracy :±0.5cm

Labeling dimension :3cm*6cm(w*l)

Air source :0.6mpa

Power :380V 50HZ 3phase

Compressed air requirement: 0.6Mpa 0.65m³/min